Engineering Experience

The following sections outline a few of my engineering projects and experiences from academia, internships and personal endeavours. Many of these projects have a clear or underlying focus on sustainability and how engineering solutions can advance the push towards a more sustainable future.

Bright Machines

Manufacturing Automation Engineer

2025 January - Present

As a Manufacturing Automation Engineer at Bright Machines in San Francisco, I design and implement updates to automation equipment used in data center assembly and operation. My role involves wiring and integrating control cabinets with Beckhoff PLCs, ensuring seamless system operation and reliability. I also focus on optimizing manufacturing processes by designing fixtures, refining documentation, and enhancing workflows to increase production rates. By improving the integration of automation systems, I contribute to more efficient and scalable manufacturing solutions that drive innovation in data center assembly.

Plenty

Senior Installation & Integration Engineer

2022 December - 2024 November

As a Senior Integration and Installation Engineer, I led the design, construction, and commissioning of advanced agricultural infrastructure—including controlled environment facilities, large-scale irrigation systems, and ozone water treatment skids. I oversaw every stage from acceptance testing to onsite commissioning, ensuring projects met operational goals while staying on time and within budget. I developed comprehensive mechanical design packages with CAD, FEA, and reliability analysis, and I hold a patent for a scalable irrigation system upgrade that supports over one million plant sites. I applied Lean Six Sigma principles to boost production line efficiency and led cross-functional safety risk assessments to ensure regulatory compliance and operational safety across complex systems.

Plenty

Mechanical Design Engineer

2021 Jan - 2022 Dec

Spearhead onsite engineering support during construction of first of its kind hydroponic leafy greens farm, coordinate with fellow engineers, general contractor and subcontractors. Design and Integration lead for thermal cladding and automated doors in Grow Spaces. Decreased construction downtime thanks to fast design turnaround utilizing Catia whole farm model

Van Conversion

Designed and executed a full conversion of an empty cargo van into a functional off-grid RV. Four years since its initial completion and everything has been working amazingly, but with a project like this, its never done, you never stop to tinker and imporve it.

-

Design & Planning: Utilized SolidWorks and physical mockups for detailed modeling and layout planning to ensure optimal space utilization and functionality.

-

Key Features:

-

Convertible Seating: Engineered a seating area that transforms into a large bed with ample storage, incorporating multi-functional furniture to maximize space efficiency.

-

Dual-Function Countertop: Created a versatile countertop that serves as both an interior workspace and an outdoor table, enhancing the usability of the van’s limited space.

-

-

Skills Applied:

-

Electrical & Plumbing: Installed and configured off-grid electrical systems and plumbing, ensuring self-sufficiency and reliability.

-

Woodworking: Constructed custom cabinetry and furniture, combining aesthetics with practical design.

-

Budget & Timeline Management: Adhered to a strict budget and timeline, optimizing resources and prioritizing essential features.

-

-

Outcome: Successfully created a self-contained RV that meets personal needs for off-grid travel and living, demonstrating strong problem-solving and project management skills.

2020 June-Oct

Viability of Sustainable Regional Air Transport

2020 Jan-May

Executive Summary

Slide Deck

Final Paper

The investigation of three broadly representative routes for, business, leisure, and small community connection in California, showed the viability of a regional airline utilizing hybrid aircrafts, such as from ZeroAvia. Only a few government incentives were shown to be needed to make this new airline model cost competitive on many of the routes while offering substantial emissions savings. In order to quantify and compare the differences in cost, emissions, and travel time, all these factors where converted into a dollar amount.

Lean Construction and Supply Chain Management Practices

Precast Concrete Supply Chain Optimization

2019-2020 Aug-May

Discrete event simulation was used to explore continues improvement opportunities in the supply chain of precast concrete piles, such as improved matching of manufacturing rate with installation schedules and arrival rate of the precast elements at the project sites. The optimization helped reduce overall project duration, supply chain costs, and improve the reliability of promises in regard to daily pile installation to avoid schedule slippage.

Modeling Example (click to enlarge)

Final Paper

Berkeley Inn Column Formwork Process Optimization

2019 Aug-Dec

Through site visits and documentation of the current state of work a clear idea of areas for improvement were established. the use of current state value stream mapping, crew balance chart, cycle time chart, swimlane diagram etc. were prepared in order to analyze the issues with respect to time and stakeholders. Suggested improvements include:

1) Work restructuring to increase productive time and decrease worker idle time

2) Pre-installation of tie-off locations on column formwork to reduce non-value-added time of climbing and searching for suitable tie-off points

3) Elimination of specific formwork oiling and cleaning location to reduce manpower and crane movement time

Executive Summary

Slide Deck

Final Paper

Life Cycle Assessment

2019 Sep-Dec

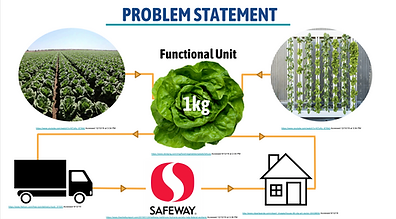

The focus of the study was to determine whether using a ZipGrow, two tower Farm Wall for home grown hydroponic lettuce production in Berkeley, California (CA) is more sustainable than traditional drip irrigation growing methods in Fresno, CA. This report analyzes the CO2e emissions of a functional unit of lettuce (1 kg) when produced at a consumer's home, using a ZipGrow Farm Wall, or when produced using traditional farming practices and purchased from a local supermarket. Packaging was the largest contributor in the traditional farming LCA, whereas electricity consumption due to the cheap inefficient sump pump supplied with such systems, was the largest contributor for the home growing hydroponic solution. The electricity consumption offset any emissions savings due to shorter travel distances and thus resulted in nearly twice the CO2e emissions per kg of lettuce for the hydroponic system.

Abstract

Slide Deck

Final Paper

Traditional Agricultural versus Hydroponic Homegrown Lettuce Production

Hydroponic Mechanical Engineering Project

2018 Jan-Dec

Team leader in charge of fluid testing, design validation and management of a cross functional team of

mechanical engineers and computer science students working on the development of a modular hydroponic system that is easy to install and maintain. The system features a novel automated centrifugal pump-free module water evacuation system, utilizing a float sensor and venturi pump.

Demo Plant Module

Demo of Automated System

Test Rig

Single Track Vehicle Design (Bike Build)

2018 Jan-Mar

Designed, manufactured and tested a commuter bicycle. Design choices were based on equations derived from

dynamic handling model of a bicycle. The bike is still used for commuting daily and is a joy to ride.